Polyethylene Oxide (PEO) Average Mv 600,000 – Electrospinning Grade Polymer

Price range: ₨5,500.00 through ₨10,500.00

High-purity Polyethylene Oxide (PEO, Mv 600,000) from MACKLIN, ideal for electrospinning, nanofiber fabrication, drug delivery research, and polymer blend modification. It has excellent solubility in water and alcohols with superior film-forming and viscoelastic properties.

Product Description

Polyethylene Oxide (PEO), also known as Poly(ethylene oxide) or Poly(oxyethylene), is a high-molecular-weight, water-soluble polymer with excellent film-forming, thickening, and rheological properties.

The MACKLIN PEO (Mv ≈ 600,000) is a research-grade polymer specifically suitable for electrospinning, nanofiber production, and composite formulation.

Its high chain length and molecular uniformity enable smooth fiber formation, stable jet behavior, and strong nanofiber networks. This makes it ideal for biomedical applications, membranes, tissue scaffolds, and polymer composites.

Technical Data Sheet (TDS) — Polyethylene Oxide (Mv 600,000)

| Property | Typical Value | Unit / Remarks |

|---|---|---|

| Chemical Name | Poly(ethylene oxide) | — |

| CAS Number | 68441-17-8 | — |

| Brand | MACKLIN | High Purity Grade |

| Average Molecular Weight (Mv) | 600,000 | g/mol |

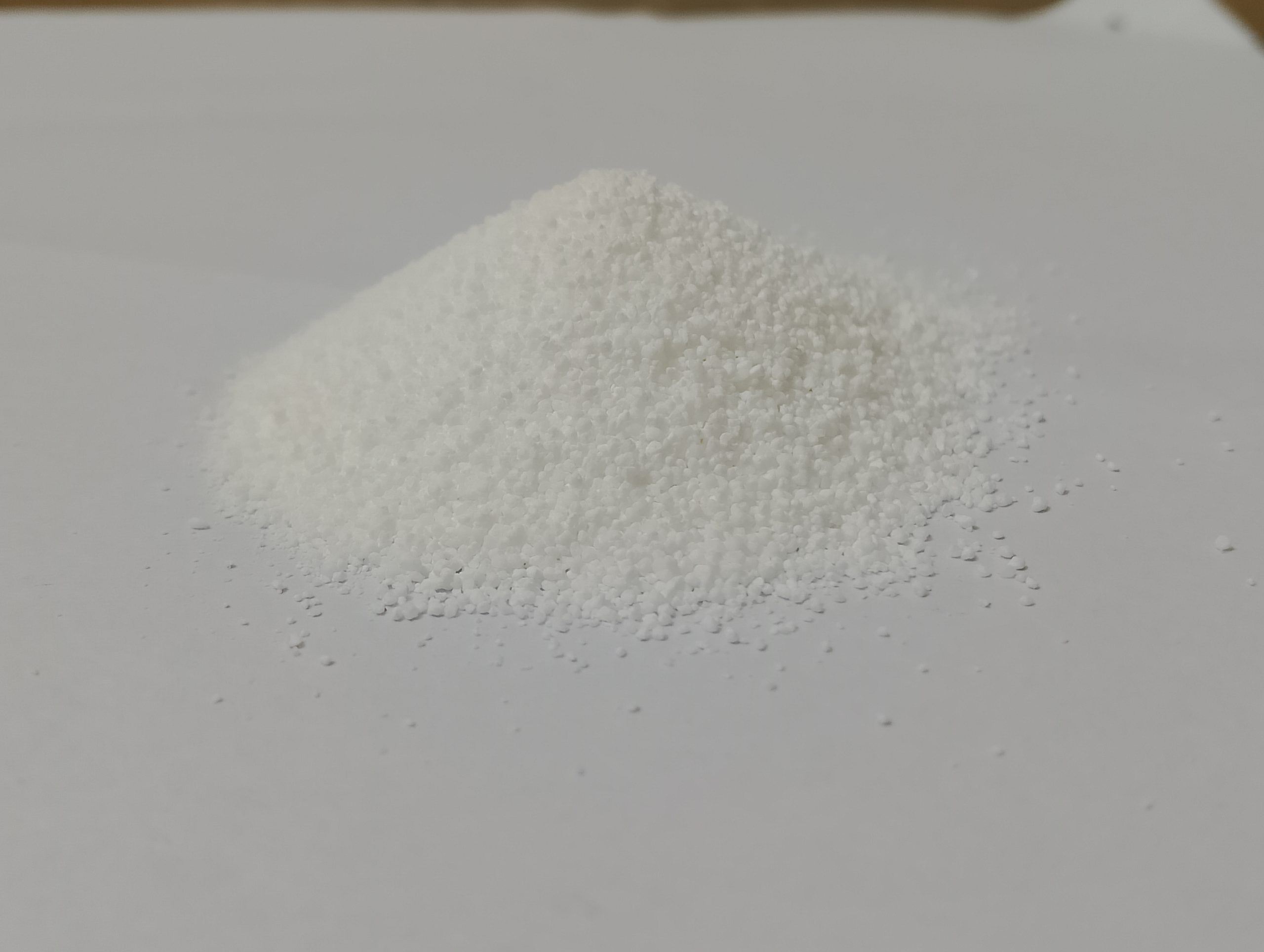

| Appearance | White to off-white powder | — |

| Purity | ≥ 99 | {b62f61b67fe4eaf465e8791cb87f2e71e17f2422c6659768cc5bdfe42275a969} |

| Density | 1.21 | g/cm³ |

| Glass Transition Temperature (Tg) | –60 | °C |

| Melting Point | 65–70 | °C |

| Solubility | Soluble in water, ethanol, methanol, isopropanol | — |

| Viscosity (1{b62f61b67fe4eaf465e8791cb87f2e71e17f2422c6659768cc5bdfe42275a969} solution, 25 °C) | 200–500 | cP |

| pH (1{b62f61b67fe4eaf465e8791cb87f2e71e17f2422c6659768cc5bdfe42275a969} solution) | 6.0–8.0 | Neutral |

| Moisture Content | ≤ 1.0 | wt.{b62f61b67fe4eaf465e8791cb87f2e71e17f2422c6659768cc5bdfe42275a969} |

| Electrical Conductivity | Non-conductive | — |

| Origin | China (MACKLIN) | Imported research grade |

*All values are typical and may vary slightly depending on testing conditions and batch.

Applications & Uses

Electrospinning & Nanofibers

- Excellent for electrospinning stable nanofibers with smooth morphology.

- Acts as a spinning aid when blended with polymers like PLA, PVA, PCL, and chitosan.

- Used in biomedical membranes, wound dressings, and tissue engineering scaffolds.

Research & Laboratory Applications

- Ideal for solution preparation, viscosity control, and polymer modification studies.

- Used in drug delivery, controlled release systems, and hydrogel synthesis.

Industrial Applications

- Thickener and rheology modifier in coatings, adhesives, and lubricants.

- Binder and stabilizer in ceramics, inks, and cosmetic formulations.

- Used in battery separators, fuel cell membranes, and 3D printing gels.