Multi-Walled Carbon Nanotubes (MWCNTs) – High Purity 99.95% Research Grade

Price range: ₨2,200.00 through ₨22,500.00

High-purity Multi-Walled Carbon Nanotubes (99.95%) with controlled tube diameter and length for advanced research, nanocomposites, conductive materials, energy storage, coatings, and high-performance polymer reinforcement. Ideal for laboratories and industrial R&D.

Product Description

Multi-Walled Carbon Nanotubes (MWCNTs) with 99.95% purity are engineered for high-precision nanotechnology applications, delivering exceptional electrical conductivity, mechanical strength, thermal stability, and high surface area. These nanotubes consist of multiple concentric graphene layers, making them suitable for reinforcing polymers, developing conductive coatings, manufacturing sensors, and enhancing battery and supercapacitor performance.

With controlled tube dimensions and minimal impurities, these CNTs disperse effectively in solvents, resins, and polymer matrices. They are widely used in material science, energy systems, electronics, biomedical research, and advanced composite development. The high purity ensures low metal catalyst residues, resulting in improved performance and more consistent experimental results.

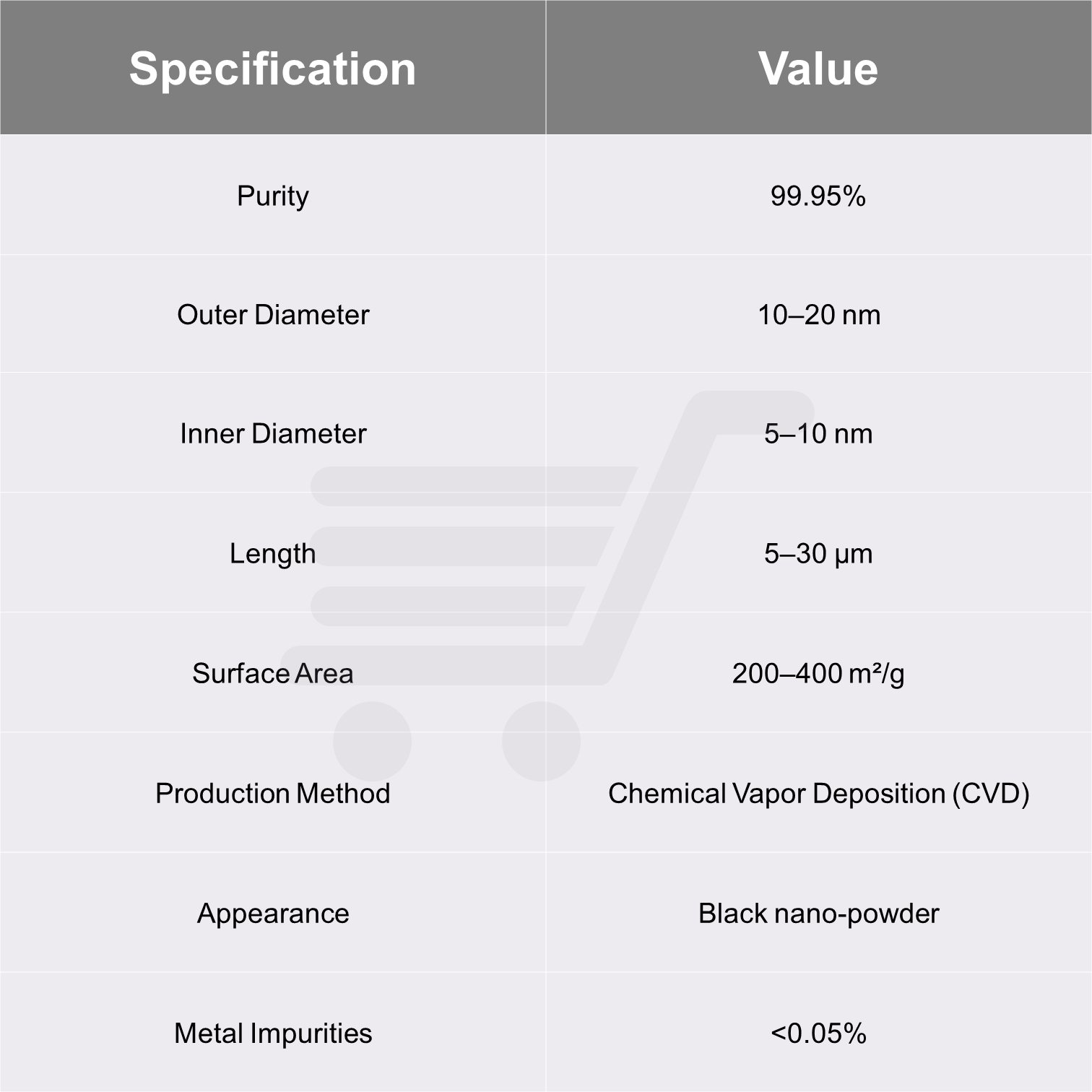

Technical Data Sheet (TDS):

| Property | Value |

|---|---|

| Product Name | Multi-Walled Carbon Nanotubes (MWCNTs) |

| Purity | 99.95% |

| Type | Multi-walled / Nanostructured Carbon |

| Outer Diameter | 10–20 nm (typical range) |

| Inner Diameter | 5–10 nm |

| Tube Length | 5–30 µm (micrometers) |

| Specific Surface Area | 200–400 m²/g |

| Electrical Conductivity | High |

| Thermal Stability | >600 °C in inert atmosphere |

| Bulk Density | 0.05–0.15 g/cm³ |

| Appearance | Black powdered nanotubes |

| Production Method | CVD (Chemical Vapor Deposition) |

| Metal Impurities | <0.05% |

| CAS Number | 308068-56-6 |

| Storage Conditions | Store in sealed container, dry environment |

| Shelf Life | Stable under recommended storage |

Uses of Multi-Walled Carbon Nanotubes:

• Reinforcement of polymer composites (thermosets and thermoplastics)

• Conductive coatings, conductive inks, and antistatic materials

• Battery electrodes and supercapacitor enhancement

• EMI shielding and electrical conductivity improvement

• High-performance adhesives and resins

• Nano-sensors and electronic components

• Thermal interface materials

• Filtration membranes and nanostructured materials

• Biomedical research and drug delivery studies

• Additive for 3D printing materials

Additional Information

| Weight | 100 mg, 500 mg, 1 gram, 5 grams |

|---|